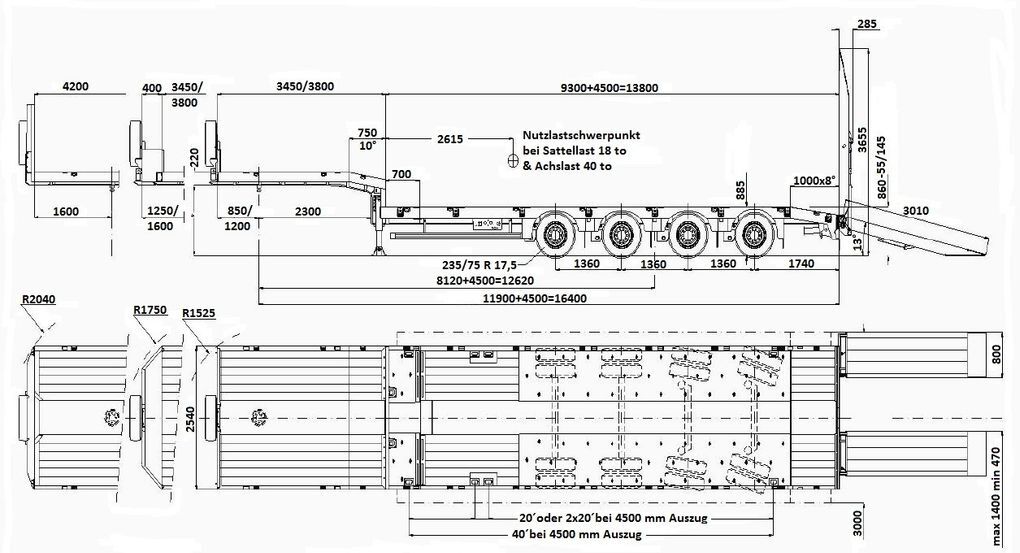

Ny Nedbygget platform sættevogn Faymonville MAX Trailer 4-Achs-Tele-Semi-nachlaufgelenkt

Publiceret: 6mån. 4d.

Publiceret: 6mån. 4d.

Har du brug for forsendelse?

Pre-purchase inspection

Pre-purchase inspectionGooseneck:

Gooseneck with beveled corners at 45° at the front and with a bevel at the rear of approx. 750 mm x 10°.

3 pairs of lashing rings (LC 5.000 daN).

Hardwood covering 30 mm thick.

Loading floor in telescopic design:

Loading floor in telescopic design with rear chamfer (approx. 1.000 mm x 8°).

5 pairs of lashing rings, foldable to the outside (LC 5.000 daN).

3 pairs of lashing rings, foldable to the outside (LC 10.000 daN).

1 pair of lashing rings lying at the front of the loading floor (LC 10.000 daN).

Cut-outs in the outer frame of the loading area for hanging straps. (LC 2.000 daN).

Hardwood covering approx. 48 mm thick, checker plate covering over the axles.

Two-piece steel ramps:

1 pair of zinc-plated two-piece steel ramps (approx. 2.750 + 1.400 x 800 mm with hardwood floor of approx. 48 mm).

Ramp with ramp parts that can be opened and folded hydraulically, hydraulic lifting gear and can be moved hydraulically.

Maximal load per pair: 40.000 kg

Landing legs:

JOST landing legs (mechanical) with 2-speed-gear for 24 tons lifting capacity (50 tons test load).

Axles and Tyres:

BPW axles, two axles rigid, two axles self-steering, air-sprung, with drum brakes, with lifting/lowering function.

To activate the self-steering axles with electromagnetic reversing lock via reverse gear or manually.

Axle tool.

Tyres 235/75 R 17.5.

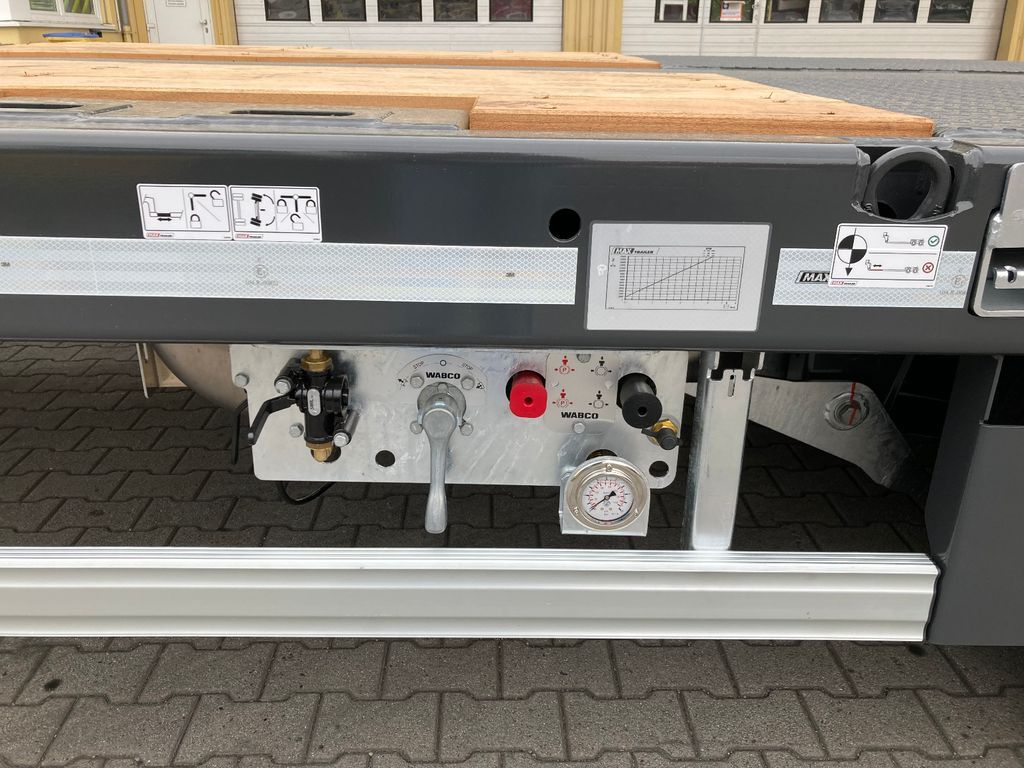

Braking system:

Braking system according to EU regulations with EBS-E (4S3M) without connecting cables to the truck.

Steel construction:

Steel construction of high-strength fine-grained steel.

Steel quality:

S355J2+N/S355MC (yield strength 355MPa)

S690QL/S700MC (yield strength 690MPa)

Painting:

First-class and long-lasting corrosion protection of the standard shot-peened welding frame guaranteed by a 2-component (2K) zinc dust primer. A high-quality 2-component (2K) single-colour top coat in Nova grey.

Rear section metallized and painted in RAL 9010 (pure white).

Metallic paintwork not possible.

Electrical system:

Electrical system according to EU regulations, lighting LED 24 volt ASPÖCK-NORDIK (ASS3).

ASPÖCK-UNIBOX on the connection strip at the front with 24N, 24S & 15-pin sockets

Connection according to ISO.

24N ISO-1185

24S ISO-3731

15-pin ISO-12098

Additional equipment:

2"-king pin.

A galvanized steel bulkhead (height ca. 400 mm).

A spare wheel with holder in front of the bulkhead.

Yellow/Red air couplings on the front of the galvanized connection strip.

4 wheel chokes with holder on the bulkhead.

Mount in the rear area of the gooseneck for ALU docking ramps.

Galvanized folding supports under the slope of the loading area.

A bracket for a warning light at the rear of the trailer.

Cover plates to bridge the space between ramps and loading area.

Red reflective tape on the side, on the pull-out and on the back in accordance with EU regulations.

Electro-hydraulic unit at the rear under the loading area.

On the gooseneck and on the ramps on the left and right, a holder for the warning signs including a socket.

Operating valves for the ramps mounted on the right side of the trailer.

A mud flap at the rear of the trailer.

Manual and description on USB stick.

ALU side walls and rear wall can be plugged onto the gooseneck, approx. 2.440 x 400 mm (L x H).

The rear galvanized stanchions are removable. (Length of the body approx. 2.560 mm).

4 pairs of WADER container bags in the loading area for a 20ft, 2x 20ft or a 40ft container.

7 pairs of stanchion pockets for stanchion 100 x 50 mm in the outer frame of the loading area.

Galvanized extensions, extendable by approx. 230 mm on each side.

Lifting axle on the front axle controlled by TEBS E depending on the current axle load and the current loading status

Square climbing strips 20 x 20 mm every 200 mm on the outer frame of the sloping loading area.

A coated layer of sand on the checker plates, over the king pin and the loading area to prevent slipping.

Central lubrication system BEKAMAX (Pico), with normal grease NLGI-2 and with removable protection around the pump.

Four warning signs approx. 423 x 423 mm, extendable by approx. 400 mm, with an LED position light.

A bracket for a warning light on the warning signs.

European reflector signs (red-yellow) on the rear of the trailer.

Speed sticker 80 km/h on the rear and on both sides.

Load manometer to determine the axle loads including load diagram.

HRM metallization (High Resistance Metallization) of the outer frame.

Complete steel construction shot-blasted, then the defined visible surfaces metallized with ZINACOR 850 (zinc 85% - aluminum 15%), hot-coated.

Har du brug for forsendelse?

Få et forsendelsestilbud

Har du brug for forsendelse?

Få et forsendelsestilbud